The Breakthrough in Welding Single Pieces and Small Batches

Efficient and Cost-Effective Welding of Single Pieces and Small Batches

Traditionally, the robotization of welding tasks for the production of single pieces and small batches has not been cost-effective.

Online programming of robots is often too time-consuming, while offline programming requires additional calibrations and corrections.

Both methods also demand specialized personnel with expertise in robotics, computer programming, and welding.

Instant Programming Offers the Solution

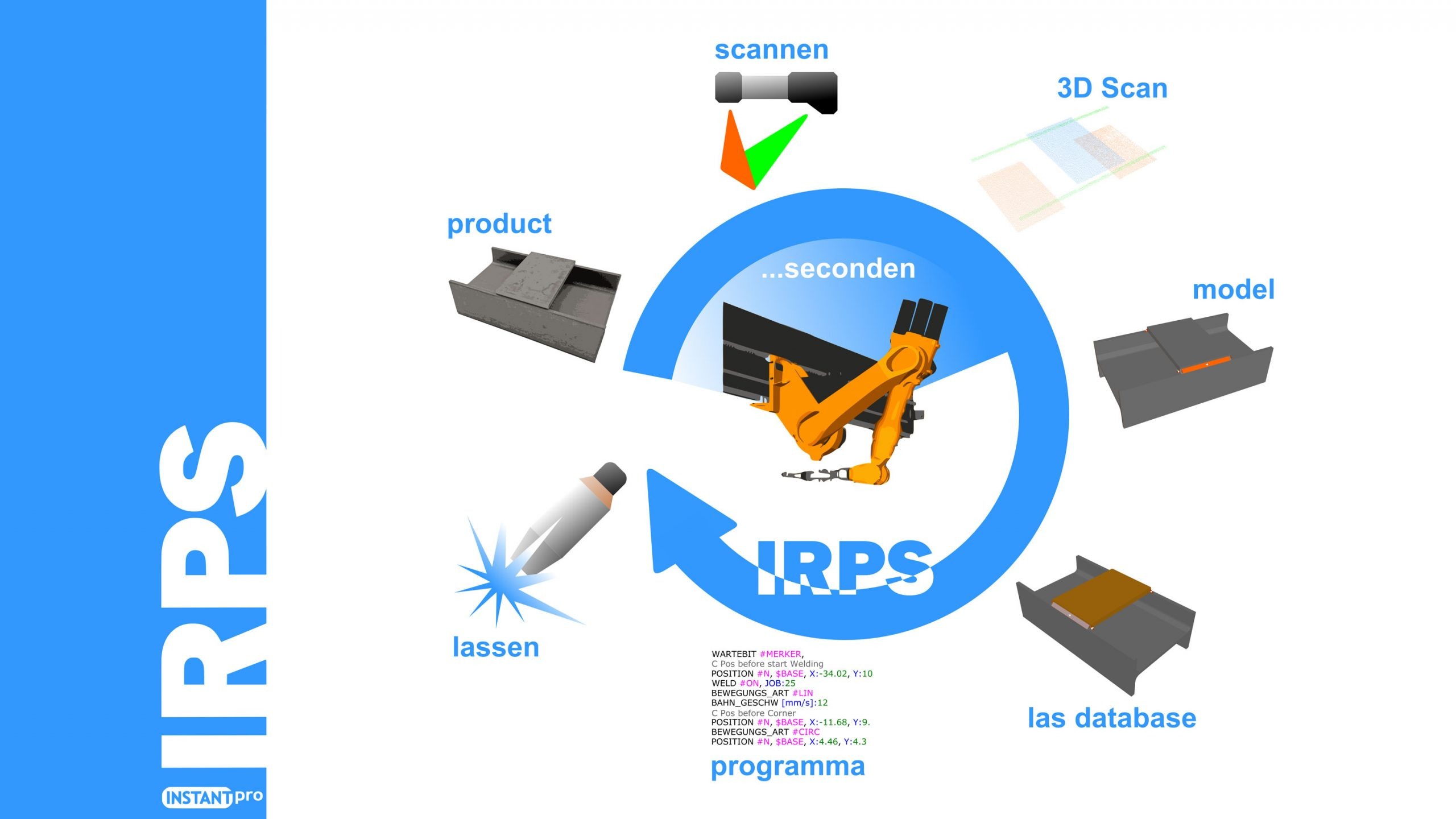

The Instant Robot Programming System (IRPS) eliminates these challenges.

The IRPS consists of a laser scanner, computer, and touchscreen that can easily be added to an existing welding robot.

The system scans the product, automatically generates a 3D model, and creates a welding program within seconds.

The robot can begin welding almost immediately.

Smart Algorithms and Customizable Welding Knowledge

The strength of the IRPS lies in smart algorithms that utilize an integrated database containing welding knowledge and experience.

This database can be easily and intuitively adjusted to meet your specific requirements, ensuring the system always aligns optimally with your production process.

Applications in Steel Construction and Fabrication

The IRPS is particularly well-suited for welding steel construction components, such as:

- Hall and bridge structures

- Shipbuilding components

- Gratings, stairs, and ladders

More Information

Would you like to learn how the IRPS can optimize your production process?

Please feel free to contact us. We are happy to assist you.